All About Truck Brake Line Repair And Replacement

Maintaining a reliable braking system is of utmost importance when it comes to the safe operation of trucks. Truck brake lines play a critical role in ensuring efficient braking performance and the vehicle’s overall safety. Over time, however, brake lines can suffer wear and tear, leading to leaks or failures that compromise braking effectiveness. That’s where truck brake line repair and replacement come into play.

Truck brake line repair and replacement involve diagnosing issues with the brake lines, addressing leaks, and restoring the system to its optimal working condition. Whether repairing damaged sections or replacing the entire brake line, this essential maintenance task ensures that your truck’s braking system operates smoothly and reliably, providing the stopping power necessary to keep you and your cargo safe on the road.

In this guide, we will delve into the world of truck brake line repair and replacement, exploring common issues that arise, the steps involved in the repair process, and important considerations to keep in mind.

Table of Contents

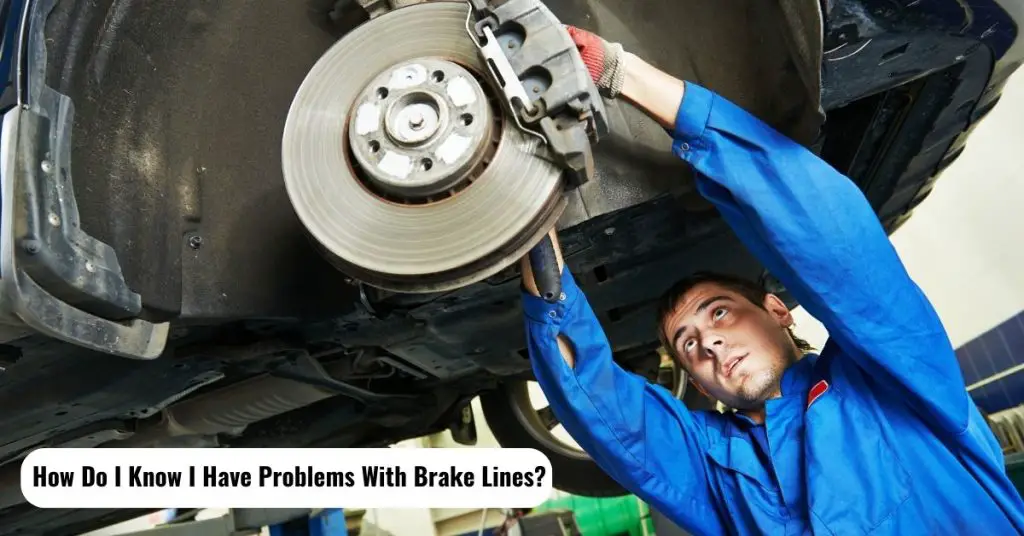

How Do I Know I Have Problems With Brake Lines?

1. Brakes Weaker

When it comes to the functionality of your car, it’s important to pay attention to anything that might seem out of the ordinary. A reduction in braking power is no exception. One tell-tale sign that something may be wrong with your brakes is if your brakes are working intermittently or there is a sudden difficulty in stopping the car.

A brake line failure could cause this, but it could also indicate worn brake pads or problems with other hydraulic components like the master cylinder.

It’s always best practice to have your car looked at by a professional whenever you notice something unusual, especially regarding your vehicle’s safety features, such as its brakes.

Doing so can help save you from potentially costly repairs and ensure that any potential hazards due to failing brakes are addressed before they become dangerous. Catching this sign means it’s time for truck brake line repair and replacement.

2. Brake Light On

When a car’s brake warning light turns on, it is a sign that there is something wrong with the braking system. Two of the most common reasons for the light to turn on are low brake fluid levels in the master cylinder or that the parking brake has been engaged. These issues can be easily fixed with a few adjustments.

If it’s low brake fluid that causes the light to turn on, this may be due to damaged brake lines somewhere in the vehicle. It is important to check these lines and repair any potential leaks not to damage your brakes even further.

It is also important to regularly check your brake fluid levels when servicing your vehicle. Low brake fluid levels can cause decreased braking performance and lead to safety concerns if not dealt with fully and correctly. If you see this sign, then don’t late run to truck brake line repair and replacement service.

3. Leaking Fluid

If you spot a puddle of brake fluid underneath your car, it is likely coming from one of the brake lines. Brake fluid is essential for braking performance; when the brake lines leak, your car will be unable to stop properly, and you will experience decreased responsiveness from your brakes.

Since brake fluid should never come into contact with dirt or debris, a leak can also damage the system.

If you spot leakage from your brake lines, a professional mechanic must inspect and repair them as soon as possible. Doing so will ensure that the brakes are safe and functioning properly when needed – like stopping your vehicle at intersections or avoiding an accident while driving.

4. Noisy Brakes

Noise from your brakes is a tell-tale sign that something may be wrong with them. Whining, grinding, and squealing noises could indicate a problem with the brake lines or other braking system components.

The issue could also range from the air in the lines to worn-out pads, but it’s best to get it checked out by a professional.

In addition to having your brakes checked out, it is important to ensure that they are in good condition and up-to-date. Worn-out brake pads can cause the same issues and must be replaced immediately for optimal performance.

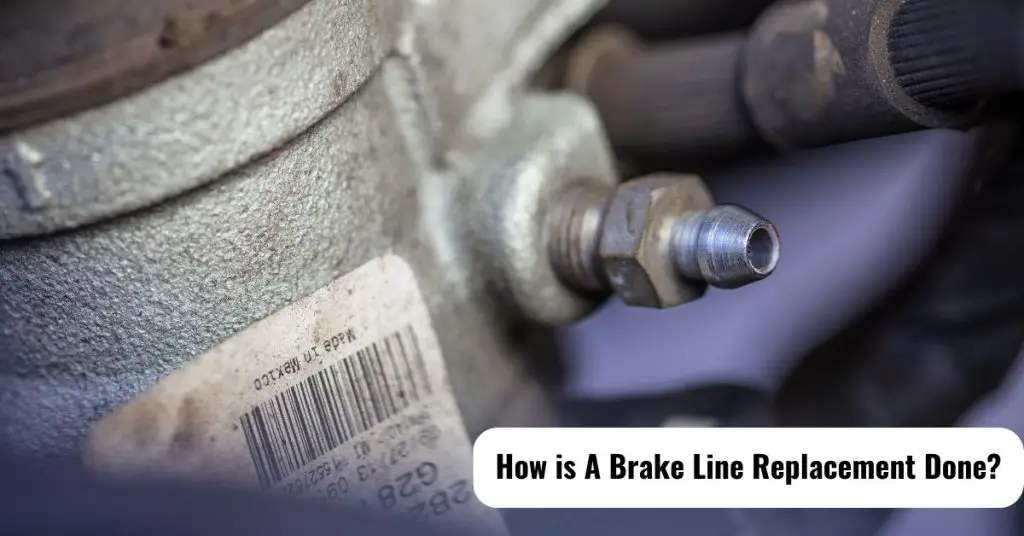

How is A Brake Line Replacement Done?

Material You May Need

Different materials can be used when repairing brake lines depending on the specific repair needs. Here’s a table highlighting common materials used for repairing brake lines:

| Material | Description |

|---|---|

| Brake Line Tubing | Metal tubing specifically designed for brake line repairs. |

| Compression Fittings | Fittings with flared ends create a secure connection between brake line sections. |

| Flare Fittings | Fittings with flared ends that create a secure connection between brake line sections. |

| Brake Line Repair Kits | Kits that include various materials needed for brake line repairs, such as tubing, fittings, and connectors. |

Instructions

Replacing a brake line is a task that requires careful attention and proper procedure to ensure the brake system’s integrity and safety. Here are the general steps involved in replacing a brake line:

- Gather the necessary tools and materials: You will need a wrench or line wrench, flare nut wrench, tubing cutter or hacksaw, brake line tubing, flare tool, brake fluid, and a container to catch brake fluid.

- Prepare the vehicle: Park on a flat surface and engage the parking brake. Ensure the vehicle is secure and will not roll during the procedure. Raising the vehicle using jack stands to access the brake lines if necessary.

- Locate the damaged brake line: Identify the specific brake line that needs replacement. Follow the line from the master cylinder to the brake caliper or wheel cylinder. Take note of any connections, fittings, or brackets securing the line.

- Remove the old brake line: Begin by carefully loosening and disconnecting the brake line fittings at each end using the appropriate wrenches. Be cautious to prevent damage to the fittings or other brake system components. If brackets or clips secure the line, remove them as well.

- Cut and prepare the new brake line: Measure and cut a new brake line of the appropriate length using a tubing cutter or hacksaw. Ensure the new line matches the old line’s size, material, and fittings specifications. Use a deburring tool or file to remove any sharp edges from the cut ends of the new line.

- Create flares on the new brake line: Use a flare tool to create the necessary flares on the ends of the new brake line. The type of flare required depends on the specific fittings used in your vehicle’s brake system. Follow the instructions provided with your flare tool to create the proper flares.

- Install the new brake line: Attach the new brake line to the existing fittings, starting from one end and working your way to the other. Use the appropriate wrenches to tighten the fittings securely, ensuring a leak-free connection. Reinstall any brackets or clips that secure the brake line in place.

- Bleed the brake system: After the brake line replacement, it is crucial to bleed the brake system to remove any air bubbles. Begin with the brake farthest from the master cylinder and gradually work to the closest brake. Follow the recommended bleeding procedure for your specific vehicle to ensure proper brake function.

- Check for leaks and test the brakes: Once the brake line replacement and bleeding are complete, carefully inspect all connections and fittings for any signs of leakage. Test the brakes by pressing the brake pedal multiple times to ensure proper brake operation and responsiveness.

Note: Following the manufacturer’s recommendations and consulting the vehicle’s service manual for detailed instructions specific to your make and model is important. If you are not confident in your ability to perform a brake line replacement, seeking assistance from a qualified mechanic is recommended. Brake systems play a critical role in vehicle safety; any mistakes or improper installation can compromise braking performance.

Frequently Asked Questions [FAQs]

1. What Is The Best Brake Line Material?

Aluminum, stainless steel, and steel are durable materials that can withstand high temperatures, making them ideal for use in braking systems that experience high temperatures and potential temperature increases.

2. How Long Do Brake Lines Last?

The average lifespan of brake lines varies depending on the material used, how well they are maintained, and the environment they are exposed to. Generally, steel brake lines can last up to 10 years, while copper-nickel lines may need to be replaced in as little as 3-5 years. It is important to regularly inspect your vehicle’s brake lines and replace them if they show signs of wear or damage.

3. What Is The Most Common Brake Line Failure?

The most common brake line failure is due to corroded or damaged metal lines. Over time, rust can build up on the brake lines, causing them to weaken and eventually fail.

This can happen more quickly in areas with high humidity and moisture levels, which can cause the metal to corrode faster. Other causes of brake line failure include excessive flexing due to rough roads, bumps, or even a manufacturing defect.

4. What Causes Brake Lines To Fail?

Brake lines can fail due to many factors, such as corrosion, overuse, or wear and tear. Rust can build up on the metal brake lines over time due to high moisture levels in the air. This can weaken them and cause them to fail eventually.

Excessive flexing caused by rough roads or bumps is another reason for brake line failure. In some cases, the brake lines can be damaged due to a manufacturing defect, leading to unexpected and unwanted failure.

5. Is Steel Or Copper Brake Line Better?

Regarding brake lines, the debate over which material is better– steel or copper – can stir up some heated opinions. Both materials have merits, and their choice often depends on personal preference.

Conclusion

Truck brake line repair and replacement are crucial aspects of maintaining a safe and reliable braking system for your truck. By understanding the common issues that can arise with brake lines and learning the necessary repair techniques, you can ensure that your truck’s brakes operate at their best, providing the stopping power needed for both everyday driving and heavy-duty tasks.