Top 10 Anti-Lock Brake System (ABS) Repair And Maintenance Tips

Regarding vehicle safety, the anti-lock brake system (ABS) is one of the most important features. It works as a safety net when you suddenly stop your car on a wet or slippery road. It helps prevent your car from skidding, ensuring the tires maintain traction and contact with the road surface during emergency braking. Like other car components, your ABS requires regular maintenance to function efficiently.

The importance of the ABS and its proper maintenance cannot be ignored, especially regarding your safety. This article will explain what ABS systems are, how they function, and how you can perform regular maintenance and give tips. So, read on and learn all of that.

Table of Contents

How Does ABS Work?

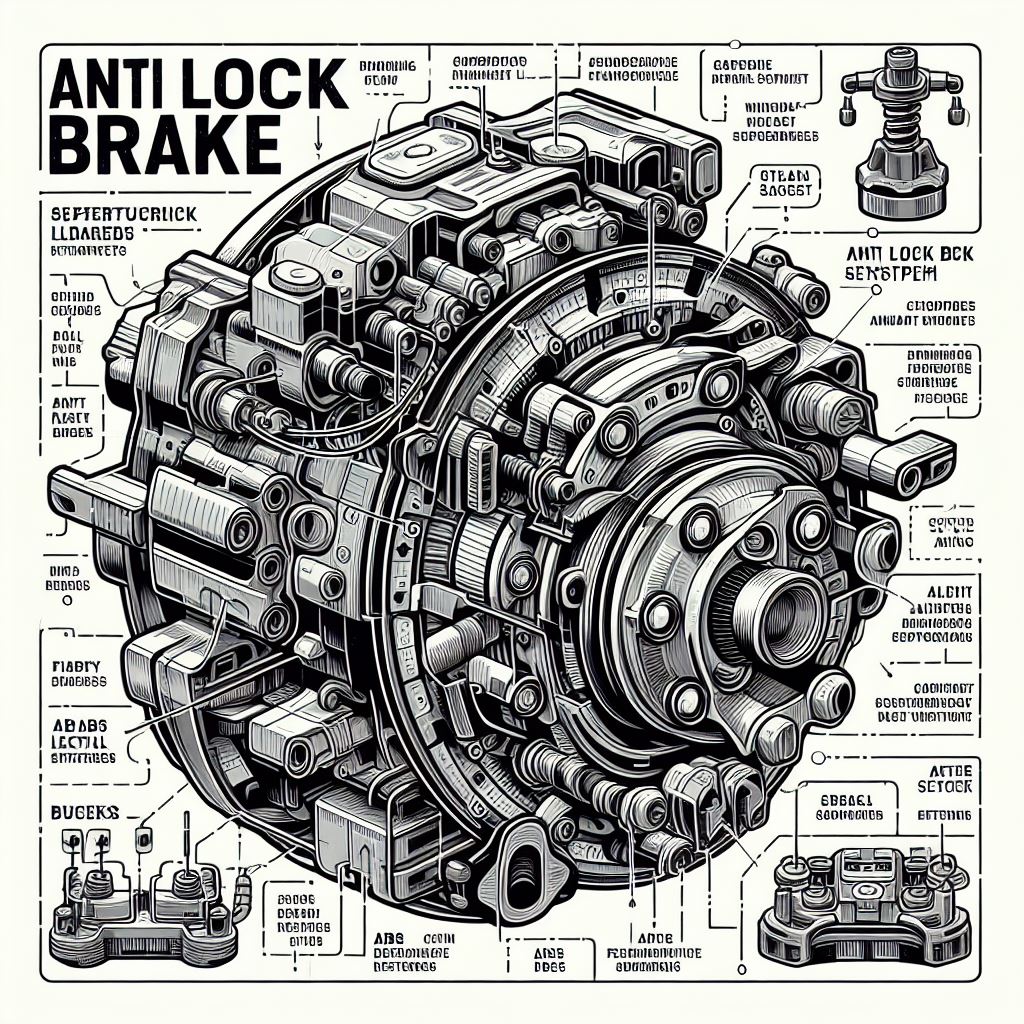

Anti-lock brakes, also known as “ABS,” are a common feature on many new cars and trucks. The purpose of these brakes is to minimize skidding when braking heavily or in difficult conditions such as wet roads or slippery surfaces. The way that anti-lock brakes work is by using a combination of several components: speed sensors, valves, a pump, and a controller.

The speed sensors detect the rate at which the wheels rotate and forward this data to the controller. The controller then uses this information to calculate how much pressure should be applied to release and reapply the brakes when necessary.

It does this by sending signals through the valves in the brake line, stopping and releasing pressure as needed, which pumps hydraulic fluid into the calipers or brake drum assemblies. This process helps regulate your stopping action so that it’s controlled even if you’re braking hard on unstable terrain with less chance of skidding or locking up the brakes entirely.

Not all anti-lock braking systems are created in quite the same way. Still, they all ultimately rely on releasing and reapplying pressure to prevent wheel lockup during hard braking situations.

Is Anti-Lock-Brakes Effective?

Anti-lock braking systems (ABS) are a feature that is becoming increasingly common in modern cars and other vehicles. ABS is designed to prevent the wheels of a vehicle from locking up during hard braking, allowing the driver to maintain control over the vehicle while stopping. Studies have also proven just how effective this technology can be regarding safety.

According to research by the Insurance Institute for Highway Safety (IIHS), the overall crash-involvement rate of passenger cars was reduced by 6%, and light trucks, including pickup trucks and SUVs, saw an 8% reduction when equipped with ABS brakes.

Fatal collisions with pedestrians, bicyclists or animals were also drastically reduced by 13% for cars and 14% for LTVs. Additionally, motorcycles equipped with ABS had a 31% lower fatal crash rate than those without.

However, it is important to note that ABS does not guarantee complete protection in specific driving conditions such as wet roads, ice or snow when there are also loose elements like gravel on the surface. This presents additional challenges that can make it harder for vehicles outfitted with anti-lock braking systems to stop even in emergencies effectively.

Here are10 Anti-Lock Brake System (ABS) Repair and Maintenance Tips

1. Regularly inspect the brake system for any signs of wear and tear, including the ABS components. If any parts show deterioration, replace them as soon as possible.

2. Check the connection between the ABS modulator and the master cylinder every time you change your oil or rotate your tires. Make sure all connections are secure and tight to avoid leaks or malfunctions.

3. Bleed the brake system at least once a year to remove any air bubbles that may have gotten into the lines and affected ABS performance.

4. Test your brakes on wet roads or surfaces to ensure your ABS works correctly and responds effectively in emergencies.

5. Ensure that all tires are inflated and balanced properly, as this affects how quickly the wheels can decelerate and stop, which is essential for ABS to work properly.

6. Have your ABS checked at least once a year by an experienced mechanic to ensure it functions as it should.

7. If your vehicle has been in a crash or sustained any impact, inspect the ABS before driving it.

8. Always use the recommended brake fluid for your car, as using a different type of fluid can damage the ABS and cause it to malfunction.

9. Make sure you’re regularly checking the brake pedal for any signs of sponginess or hardening, as this may indicate a problem with the ABS.

10. If you notice any changes in how your brakes are functioning, such as a delay when you press the pedal or pulsing of the ABS light, have it checked immediately by a mechanic.

DIY vs Professional Repairs of Anti-Lock Brake System (ABS)

When it comes to maintaining and repairing your vehicle’s Anti-Lock Brake System (ABS), there are two options: DIY or professional repairs. While some car enthusiasts may take pride in fixing their vehicles, others may prefer leaving it to the experts. So, which approach is better for your ABS? Let’s explore the top 10 tips for ABS repair and maintenance to help you make an informed decision.

Regularly check the brake fluid level and top it up if necessary. Low brake fluid can affect the functioning of your ABS.

Inspect the ABS sensors for any dirt or debris and clean them if needed. These sensors are crucial in detecting wheel speed and providing accurate data to the ABS control module.

Keep an eye on the condition of the ABS control module. If it shows signs of corrosion or damage, it may need to be replaced.

Don’t ignore any warning lights on your dashboard. These lights indicate an issue with the ABS and should be addressed immediately.

If you notice any unusual noises or vibrations when braking, it could be a sign of a faulty ABS. Get it checked by a professional to avoid further damage.

Pros and Cons of DIY Repairs

Maintaining your vehicle’s anti-lock brake System (ABS) is crucial for safe and smooth driving. While some may opt for professional repairs, others prefer the DIY route. But like most things, there are pros and cons to both options.

On one hand, DIY repairs can save you money and give you a sense of accomplishment. On the other hand, without proper knowledge and tools, you risk making costly mistakes. To help you make an informed decision, here are the top 10 ABS repair and maintenance tips to ensure your DIY repairs are successful and safe.

Benefits of Professional Repairs

Maintaining your vehicle’s anti-lock brake System (ABS) is crucial for safe driving. Here are the top 10 tips for professional ABS repair and maintenance. First, always check your brake fluid levels and replace if necessary.

Second, regularly check for any warning lights on your dashboard. Third, get your ABS serviced by a certified mechanic at least once a year. Fourth, make sure to follow the manufacturer’s recommended maintenance schedule.

Fifth, keep your ABS sensors clean and free of debris. Sixth, pay attention to any unusual noises or vibrations while braking. Seventh, replace worn-out brake pads and rotors promptly.

Eighth, avoid harsh braking and excessive pressure on the brake pedal. Ninth, keep your tires properly inflated for better ABS performance. And finally, never ignore any signs of a malfunctioning ABS.

These simple yet effective tips will ensure the proper functioning of your ABS and a safe driving experience.

Frequently Asked Questions [FAQs]

1. Can ABS System Be Repaired?

Yes, ABS systems can typically be repaired if they malfunction. However, the system’s complexity can make it difficult to troubleshoot and repair without specialized knowledge and tools.

The components of an ABS include Electronic Control Units (ECUs), wheel speed sensors, brake pressure modulators, hydraulic control valves, and various other components. If any component is malfunctioning or has failed, it should be replaced by a qualified professional.

2. How Often Should I Have My ABS System Inspected?

You should have your ABS inspected at least once a year or every 10,000 miles, whichever comes first. This is to ensure that the system is working properly and to prevent potential problems. Additionally, you should always get your brakes checked after any collision or impact to ensure that the ABS is still functioning correctly.

3. What Is ABS Or Anti-Lock Brakes?

Antilock brakes, or ABS, is an automobile safety system that prevents the wheels from locking up during hard braking situations. This helps the driver maintain vehicle control, even if they need to make an emergency stop.

The ABS system uses a set of sensors to monitor the speed of each wheel individually and can detect when one or more wheels are about to lock up. When this happens, the system rapidly pulses the brakes to prevent wheel lockup and maintain traction.

4. Can You Clean ABS Sensors?

Yes, cleaning ABS sensors to repair and maintain an anti-lock brake system (ABS) is possible. The ABS sensors are located near the wheel, and they sense the speed of the wheel in order to adjust brake pressure dynamically. Therefore, if these sensors become dirty or caked with debris, it can lead to errors in the braking system.

5. What Can Damage ABS Sensor?

A variety of factors can damage ABS sensors. Common causes of damage include dirt, debris, and corrosion that accumulate over time due to exposure to the elements. Other causes of ABS sensor damage are excessive heat, vibration from road conditions, or improper installation. In some cases, the ABS sensor may become physically damaged if subjected to impacts from objects such as rocks or potholes.

Conclusion

Anti-Lock Brake Systems (ABS) is an important safety feature that should be regularly inspected and maintained. It is important to ensure all tires are inflated properly, have the ABS checked annually, use the correct brake fluid, and inspect the brake pedal for any signs of sponginess or hardening. If any braking performance changes or ABS light pulsing occur, it is important to have it checked immediately by a qualified professional.