How Do Elevator Brakes Work? Everything You Need to Know

How do elevator brakes works? Elevator brakes are an essential safety feature that helps to keep the elevator from falling. The two types of brakes used in elevators are friction brakes, and electromagnetic brakes. Both brakes work by using friction to stop the elevator from moving.

Elevator brakes are an essential safety feature that helps to keep the elevator from falling. The two types of brakes used in elevators are friction brakes, and electromagnetic brakes. Both brakes work by using friction to stop the elevator from moving.

There are many types of brakes, but friction brakes are the most common brake that is used on elevators. They work by pressing two metal plates together to create friction. This friction slows down the elevator and eventually stops it.

Elevators of all types use friction brakes, including hydraulic, traction, and gearless elevators.

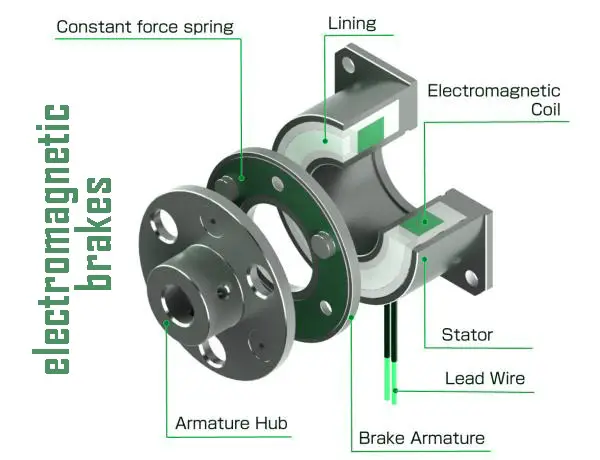

Electromagnetic brakes are less standard than friction brakes, but they are often used on high-speed elevators. An elevator’s electromagnetic brakes use magnets to slow it down.

What is the purpose of elevator brakes?

Elevator brakes are a crucial safety feature that helps to prevent accidents. They are typically located at the top of the elevator shaft and work by engaging when the elevator reaches a certain height. This prevents the elevator from falling if the cables were to snap. Without elevator brakes, elevators would be much more dangerous.

While they may not seem like it, elevator brakes are an essential safety feature. They help to prevent accidents by engaging when the elevator reaches a certain height. This ensures that the elevator will not fall if the cables snap.

Elevator brakes are vital for ensuring passenger safety. Engaging at a certain height help to prevent falls should the unthinkable happen, and the cables snap. With such an important role, it’s clear that elevator brakes are here to stay.

Are there any new developments in elevator brake technology?

Yes, there are new developments in elevator brake technology. One recent development is the use of electromagnetic brakes. These brakes are used in place of traditional mechanical brakes and offer a number of advantages.

Another new development is the use of regenerative braking. This braking system captures energy that would usually be lost as heat and uses it to power the elevator motor. This can result in significant energy savings.

As the elevator begins to move too fast, braking systems will grab the rail.

If a power outage occurs, electromagnetic brakes will stop the elevator. For extra safety, the elevator shafts are equipped with shock-absorbers, usually pistons in oil-filled cylinders, that cushion the elevator car’s landing at the bottom of the shaft.

Source: champion-elevator.com

How do emergency brakes on elevators work?

When the emergency brake is applied on an elevator, it engages a set of brakes located at the top of the elevator shaft. These brakes are designed to stop the elevator from moving in an emergency.

The emergency brake can be activated by either the elevator operator or a passenger in the event of an emergency.

When the brake is activated, it will cause the elevator to stop and remain in place until the situation has been resolved.

Emergency brakes are an essential safety feature on elevators and are required by law in many jurisdictions. They provide a way to safely stop the elevator in case of an emergency and can help prevent injuries or even death.

How are elevator brakes tested?

Elevator brakes are a vital safety component, so they must be tested regularly to ensure they function correctly. Two main tests are conducted on elevator brakes – static and dynamic.

- Static tests involve checking the brake while the elevator is not moving. This allows for a thorough inspection of all the brake components.

- Dynamic tests are conducted while the elevator is in motion, and these tests focus on how the brake performs under stress.

Both static and dynamic testing is vital to ensure that elevator brakes are working correctly and can safely stop the elevator in an emergency.

What are the consequences of failing to maintain elevator brakes?

An elevator braking system is one of the most essential safety features in a tall building. If the brakes are not properly maintained, the consequences can be catastrophic.

A failure to maintain elevator brakes can lead to a sudden loss of power, which can cause the elevator to fall free. As a result, serious injuries may occur or even death. In addition, a malfunctioning brake system can cause an elevator to become stuck between floors, trapping occupants inside.

A preventable elevator accident can be prevented with proper maintenance of the braking system. In addition, building owners and managers should ensure that their elevators are regularly inspected and that any necessary repairs are made promptly.

Hydraulic Elevators

Hydraulic Elevators are a type of elevator that uses a hydraulic system to move the elevator up and down. The hydraulic system consists of a piston connected to the elevator car.

They are powered by a piston that is filled with oil. When the elevator is called to a particular floor, the oil is forced into the piston, which in turn pushes the elevator up.

The higher the elevator goes, the more pressure is exerted on the piston, and the more oil is required to keep it moving. That’s why hydraulic elevators are often equipped with large tanks of oil – to make sure that they can handle even the longest journeys.

The advantage of hydraulic elevators is that they are very smooth and quiet. They are also very reliable and require less maintenance than other types of elevators.

Roped Elevators

Roped elevators are a type of elevator that uses ropes to move the elevator car. Two types of ropes can be used: steel and synthetic.

- Steel ropes are the most common type of rope used in roped elevators. They are strong and have a long lifespan. However, they are also heavy and can be challenging to work with.

- Synthetic ropes are lighter and easier to work with, but they are not as strong as steel ropes and have a shorter lifespan.

Roped elevators can be either traction or hydraulic. Traction roped elevators use pulleys to move the elevator car up and down. Hydraulic roped elevators use a hydraulic cylinder to push the elevator car up or down. Both types of roped elevators have their advantages and disadvantages.

Advantages and Disadvantages of Steel Ropes:

|

Advantages |

Disadvantages |

|---|---|

|

|

Advantages and Disadvantages of Synthetic Ropes:

|

Advantages |

Disadvantages |

|---|---|

|

|

Users must weigh the pros and cons before deciding which type of rope to purchase

Both hydraulic and rope-operated elevators rely on a number of safety features if they fail. Steel ropes provide an initial defense against falling objects by acting as their first line of protection. A single steel rope can support the weight of the elevator car.

Braking systems help prevent an elevator from going too fast. An electromagnetic brake stops the elevator if there is a power failure. The bottom of the elevator shaft has a shock absorber system that cushions the elevator car’s landing if other safety systems fail.

Knowing how an elevator works is important for keeping them running smoothly.

How often do elevator brakes need to be serviced?

Elevator brakes are one of the most important safety features in any building. They need to be serviced regularly to ensure that they are working properly.

Most experts recommend that elevator brakes be serviced at least once a year. However, some buildings with high traffic may need to have their brakes serviced more often. If you notice any problems with your elevator brakes, you should have them serviced as soon as possible.

If you take good care of your elevator brakes, they should last for many years. However, it is important to keep an eye on them and have them serviced on a regular basis so that they stay in good working condition.

How do Elevator Brakes Work FAQs:

What is an Elevator?

An elevator is a mechanical device used to transport people or goods between floors of a building

What is a counterweight?

A counterweight is a weight that offsets the weight of another object. The purpose of a counterweight is to create balance. Without counterweights, many objects would be too top-heavy and would topple over.

Counterweights are an important part of many everyday objects, such as doors, windows, and escalators. They help keep these objects in good working order and prevent them from tipping over or collapsing.

What is an elevator governor?

An elevator governor is a device that helps control an elevator’s speed. It is important to have this device in place so that the elevator does not go too fast and become dangerous.

The governor works by using a series of weights and pulleys to slow down the elevator as it goes up. This system is put in place so that if the power to the elevator were to fail, the governor would still be able to keep the elevator from going too fast.

How do elevator brakes work with escalators?

Elevator brakes are designed to stop the elevator car from moving when there is an obstruction on the tracks. However, if an escalator is located next to an elevator, the brake may not be able to properly engage, potentially causing the elevator to crash down onto the escalator.

Do hydraulic elevators have brakes?

Most hydraulic elevators have brakes. The brake is engaged when the elevator is not in use and prevents the elevator from moving.

The brake is released when the elevator is called to move up or down.

The brake is an important safety feature of the hydraulic elevator. If the brake fails, the elevator can fall and cause serious injury or death.

Conclusion:

In conclusion, elevator brakes are a vital part of the safety system for these devices. Without them, passengers would be at risk of serious injury or death in the event of a malfunction.

While the inner workings of elevator brakes may seem complicated, the technology is actually quite simple and has been perfected over many years to ensure the safety of those who ride in elevators every day.