How Do Brake Drums Work? [The Springs, Shoes, and More]

The braking system consists of two main components: the drum (the part that rotates) and the shoes (the pads). When you press down on the brakes, the shoes hit the drum and stop it from rotating. This stops the car or truck from moving forward.

Have you ever wondered how drum brake work? Well we are here to give you a clear insight of how it works.

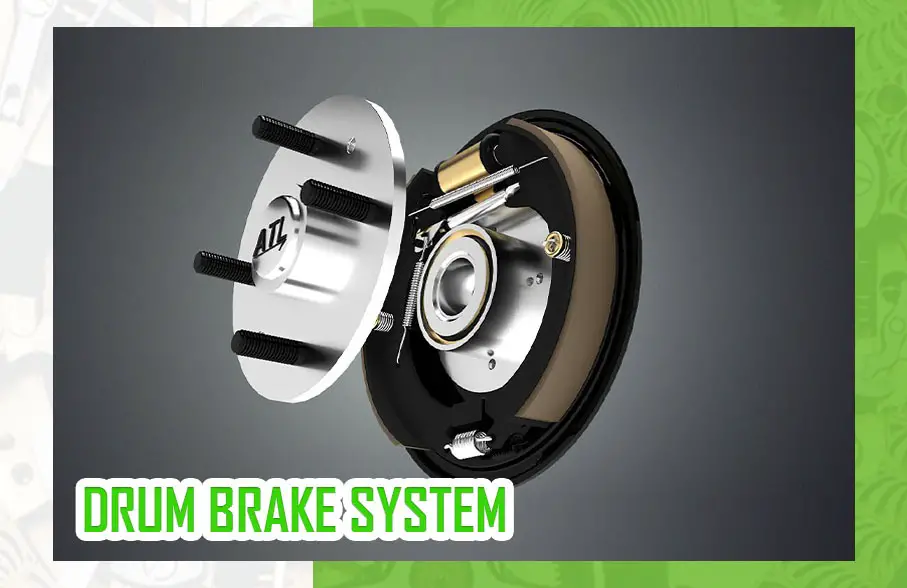

Brake drums are a part of the drum brake system

The brake drum is a cylindrical drum that is attached to the wheel hub. It’s the rotating part of the drum brake system and houses two springs, which apply pressure when you step on your brakes. The shoes are mounted on each end of the springs and are curved in shape to act like a brake pad or shoe.

When you press down on your pedal, it pushes down against one side of each spring pushing them closer together until they reach their maximum distance apart (which varies).

This moves both shoes inward toward each other applying force against the inside surface of both sides of your brake drum—which causes friction between them and your rims

Usually, they touch at two points: once where they make contact with each other inside your wheel; again where they make contact with either surface outside (rim).

Due to the pressure applied by spring(s), friction created during contact causing heat loss/gain helps regulate temperature levels of the surrounding components within systems.

Thus, helping prevent overheating issues due to prolonged periods of usage for safe operation despite conditions present at time frame being used

Drum brakes use the friction between two shoes and a rotating drum to slow a vehicle.

Drum brakes use the friction between two shoes and a rotating drum to slow a vehicle. The brake shoes are pressed against the inside of the drum and held in place by spring tension. Pressing down on the pedal increases hydraulic pressure, forcing the brake shoes against a rotating disc (the drum).

Friction material is applied to both sides of each shoe, creating increased friction when they come into contact with each other or with surfaces inside their respective cylinders.

The braking system uses hydraulic pressure to force the shoes against the drum.

In the brake system, hydraulic pressure pushes the shoes against the drum. The hydraulic pressure is generated by pushing down on a brake pedal, which in turn activates a master cylinder. This is a small metal container filled with brake fluid.

As you push down on the pedal, fluid from inside the master cylinder flows into another section called a proportioning valve. The proportioning valve mixes some of its contents with air from outside and sends it into your brake lines via hoses that run between your wheels and car body to each wheel’s caliper.

The caliper then creates more force than necessary to slow down your vehicle quickly enough so as not to cause skidding or loss of control on slippery roads (which can lead to accidents).

That extra force is converted into thermal energy by transferring heat from both sides of each piston through metal-to-metal contact; this converts mechanical energy into thermal energy because it takes less energy for molecules in solid materials like steel or aluminum than liquid ones such as water or oil when they’re at similar temperatures:

How Brake Drums Work?

Brake drums are a part of the drum brake system. Drum brakes use the friction between two shoes and a rotating drum to slow a vehicle. The braking system uses hydraulic pressure to force the shoes against the drum and cause it to rotate, which forces air from between them and creates friction.

This heats up both parts of the brake, creating even more resistance and slowing down your car faster than any other type of brake would be able to do on its own.

Spring tension keeps the shoes away from the drum while they’re not being used.

It’s important to understand how the spring tension works. The brakes are held away from the drum by a spring. This spring allows you to adjust the pressure needed to push them against it when you step on your brake pedal.

When you step on your brake pedal, hydraulic pressure is supplied to both sides of this mechanism through a master cylinder and pushes each shoe away from its respective side of the drum face.

When you step on the brake pedal, hydraulic pressure increases.

When you step on the brake pedal, hydraulic pressure increases. The hydraulic system pushes pistons against the rear of each brake shoe, forcing them against the rotating drum. That creates friction, slowing and eventually stopping the wheels – and your car.

Hydraulic pressure pushes pistons against the rear of each brake shoe, forcing them against the rotating drum.

The hydraulic pressure generated by the master cylinder is transmitted to each caliper through brake lines and push rods. This pushes pistons against the rear of each brake shoe, forcing them against the rotating drum.

The amount of effort required to stop your car depends on how much pressure is applied by these pistons. Loads of different factors influence this—like how hard it is for your foot to press down on your brake pedal, or if you’re driving in snow (which reduces friction).

That creates friction, slowing and eventually stopping the wheels – and your car

The next time you’re stopped at a red light, look at the brake shoes. They should be pressing against the drum and creating friction between them.

As you press down on your brake pedal, more pressure is applied to this system and more force is created between the brake shoes and the drum. This causes that side of your car to slow down or stop completely—and eventually stops your entire car from moving forward (and backward).

The brake shoes are in constant contact with the inside of the drum due to friction and spring tension.

The brake shoes are in constant contact with the inside of the drum due to friction and spring tension.

The brake shoes are held in place by spring tension.

The hydraulic pressure forces the brake shoes against the drum, which causes them to make contact with it.

Heat builds up as you apply and release your brakes repeatedly during normal driving conditions.

Heat builds up as you apply and release your brakes repeatedly during normal driving conditions. When you use your brakes, friction creates heat. Heat is simply a by-product of the friction that occurs when metal comes into contact with metal under pressure and speed.

Brake pads are made of a mixture of materials that create more surface area for braking action, but they are still subject to heat damage if abused—especially by repetitive use or poor maintenance over time.

The heat can damage or burn up some components within your braking system, including your brake drums.

The heat can damage or burn up some components within your braking system, including your brake drums.

In addition to being subject to excessive heat, brake drums are also susceptible to corrosion. If a drum becomes rusted, it can fail completely and cause your vehicle to lose braking power—which would be bad news for anyone behind you at the time!

Brake drums work in concert with other components to form a basic braking system for your vehicle.

A brake drum is one component of a more complex braking system. It works in concert with other components to form a basic braking system for your vehicle, but it’s not sufficient on its own. The brake drum has many parts that work together, including:

- Disc brake rotor

- Disc brake pads

- Brake caliper (also called a caliper bracket or pin)

These components are shaped like rings and fit around each other in an assembly called the disc brake rotor housing.

When you press down on the brakes, you’re pressing against these surfaces and causing them to rub against each other until they generate heat.

That heat creates resistance that slows down your car, which is why your wheels screech when you hit the brakes at high speeds!

Also check what are anti lock brakes and how do they works Follow the link: https://brakeshub.com/what-are-anti-lock-brakes-how-do-they-work/

FREQUENTLY ASKED QUETIONS

1. What is the difference between a drum and a disc brake?

Brake drums and disc brakes are both used to slow down or stop a vehicle. The main difference between the two is that a brake drum is a cylindrical shape, while a disc brake is a flat, circular shape. Disc brakes are more common in newer vehicles, as they tend to be more effective and durable than brake drums.

Disc brakes work by using calipers to squeeze pads against the spinning disc, which slows the vehicle down. Brake drums work similarly, but instead of pads squeezing against a disc, shoes press against the inside of the cylindrical drum.

While both types of brakes are effective, disc brakes tend to perform better in most situations. Disc brakes dissipate heat more effectively than brake drums, meaning they are less likely to overheat and fail.

2. How do brake drums work?

When you step on the brake pedal, hydraulic pressure from the brake fluid forces the shoes outwards. The shoes press against the inside of the drum, and this creates friction. The friction slows down the wheel and eventually brings it to a stop.

The shoes are made of a material that is designed to create a lot of friction, but they can only do their job if they’re in contact with the drum. In order for this to happen, there are springs that hold the shoes against the drum.

When you step on the brake pedal, hydraulic pressure from the brake fluid forces the shoes outwards and presses them against the inside of the drum. The amount of pressure you apply to the pedal determines how much force is exerted on the shoes and how quickly they’ll stop the wheel.

3. What are the different types of brake drums?

There are two types of brake drums: internal expanding and external contracting. Internal expanding drums hav shoes that press against the outside of the drum when the e a set of shoes that press against the inside of the drum when the brakes are applied. External contracting drums have a set of brakes are applied.

Both types of brake drums work by using friction to slow down or stop the vehicle. The shoes on the brake drums press against the rotating drum, which in turn slows down or stops the wheels from turning.

The amount of pressure that is applied to the shoes determines how much braking power is generated. The main difference between these two types of brake drums is how the shoes are able to move in order to create friction. With an internal expanding drum, the shoes are able to move outwards in order to create friction.

4. What are the benefits of using brake drums?

When it comes to keeping your car safe on the road, brakes are a vital component. And at the heart of your brake system are the brake drums – where the brakes actually make contact with the wheel to slow or stop its rotation.

But why use brake drums instead of other options? For one, they offer increased safety thanks to their heat dissipation abilities.

Plus, their enclosed design protects against damage from outside elements and debris. And let’s not forget about cost effectiveness – brake drums offer an affordable choice for all types of vehicles.

So when it comes time for a brake check, don’t forget about those trusty drums! Keep them in good shape for reliable stopping power mile after mile.

Conclusion

We hope that you have a greater understanding of how your brakes work, as well as some new knowledge about their components. The brake drum is an important part of the braking system and should be checked regularly to ensure it’s in good working order.